3D laser scanning as-built is a term that describes the absolute precision 3D laser scanners offer to your construction. We already know that all major renovation projects in Ontario require building permits.

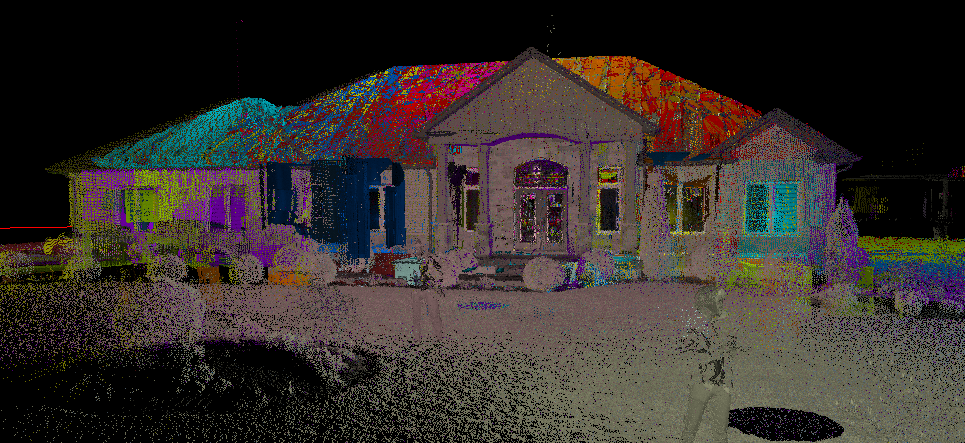

But before permit drawings can be produced, “as-built” must be created. Existing homes of all vintage (year built) can have unusual conditions that will affect future proposed designs. When we take advantage of the crystal clarity that 3D laser scanning technology brings to as-built documentation, we ensure that all peculiarities are accurately accounted for. This, in turn, paves the way for seamless renovations.

What is 3D scanning in architecture?

You must have accurate site measurements when planning a renovation or addition to your home. But on many occasions, we do not give this step the meticulous attention it deserves. This lack of precision can lead to significant issues during the design planning. This is why 3D laser scanning as-built is beneficial in construction.

What are the risks of not using 3D laser scanning in construction?

Inaccuracy in as-built measurement using traditional methods (as opposed to 3D laser scanning) can harm the design planning process. However, adopting 3d laser scanning as builts makes it easier to capture the proper measurements. Here’s what happens without 3D laser scanning in construction and with it.

- The overall design might need to accurately represent the dimensions of the existing space, potentially affecting the placement of windows, doors, millwork, and so on. 3D laser scanning, as built, offers precise, real-time data, which solves the issue.

- The retention of the existing mechanical duct layout becomes a crucial determinant of the proposed designs, and its exact position needs to be on the as-built drawings. In contrast, using 3D laser scanners captures every detail.

- There can be impacts to the existing structure if load-bearing walls are inaccurately located or lead to safe conditions; 3D laser scanning specifically addresses this issue.

This is just the beginning of the headaches that arise during design planning when measurements don’t reflect a space’s actual room size. These omissions in the as-built drawings add to design meetings due to inconsistencies.

However, these errors in as-built measurements also extend the review process conducted by others and further complicate the project, for example:

- The structural engineer must know the exact span between existing supports to specify the structural member accurately. Hence, they may want additional site verification.

- The mechanical engineer needs to know the number of vents, the sizes, and the location of duct and window sizes for heat loss calculations. These measurements reduce the guesswork, and 3D laser scanning technology can enhance that accuracy.

- The plan examiner must verify that room sizes and windows comply with the Ontario Building Code. To do so, the drawings must have accurate dimensions. All these do not add to the need for accurate measurements, which is why you need 3D laser scanning for as-built documentation.

What are the benefits of 3D scanning in design?

So, how do we avoid a site measurement defect snowballing into the collapse of a project’s progress? Get it done using the power of a reality capture device. Remove the anxiety from a site measurement with 3D laser scanner technology. Capture all the existing site conditions intricacy in one site visit and save time.

Using a 3D laser scanner for site measurement, the data is extracted to 1/16″ precise, allowing accurate as-built documentation to be prepared. This data used to create detailed as-built drawings can be relied upon during all stages of design planning, permit production, construction monitoring, and building inspection. By using this technology, potential design issues can be identified early on in the planning process.

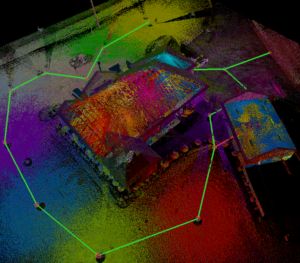

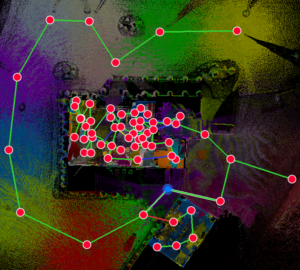

Furthermore, the point cloud output file from the 3D laser scanner can be shared and viewed on a web browser, allowing for effective communication and understanding of the project as soon as the site measure is completed. This method of early collaboration in a 3D environment between architects, other consultants, contractors, and clients benefits the project outcomes.

What does it cost to own a 3D scanner?

Most professionals think 3D laser scanning is out of their reach. And civilians need to learn this technology is used in their neighbors’ back yard. The typical cost of a 3D scanning device for scanning properties such as a house or commercial building can range between $50,000.00 to $150,000.00, depending on the range accuracy and speed required for the job.

How much does it cost to purchase a 3D laser LiDAR scanner?

The price may vary between suppliers, but the quality of the output file will be consistent with the cost of the device. With the file, you can extract information such as photos, videos, temperature, and measurements. Point cloud files offer features like live walkthrough, assessment, and markup tools to be used while discussing the scanned property. These tools included slicing through the points to create plans and sections. This data can then be shared with anyone.

How much does it cost to laser scan a house?

As technology continues to improve, these costs are expected to decrease, making 3D scanning a more accessible tool for renovation projects. However, consider using 3D laser scanning services. At the moment, each service provider will set the cost for service based on the cost of the technology. This can range from $1,500.00 to $2,500.00 for an average 1000-square-foot house. Here are some factors that determine the cost of the 3D laser scan for a renovation.

These devices require software to assemble the data collected on-site, costing thousands in subscriptions.

- Location of Property

- Interior and Exterior (setups)

- Density of Point Cloud (accuracy)

- Deadline

How long does it take to laser scan a building?

The onsite work during a laser scan project varies significantly. There is no set time, because the scan depends on the device used and the point cloud density required. However, the setup determines the time spent scanning a 1,000-square-foot house. The device allows for modification to the time it takes per complete a scan (setup) and the density (quality) of the output file. If you use a setting that speeds up the scan, you may sacrifice quality but reduce the time spent.

For example, a typically 1,000 square foot house will require between 35-45 setup (interior and exterior) and each set up to 2 minutes at a low density (1″ tolerance). This would take about 1 hour 20 min to 2 hours and 2 hours 30 min. Some devices can do the same setup in 20 seconds, significantly reducing the time on site. Ultimately, it depends on the end use of the file.

The future role of 3D laser scanning in building inspections.

Beyond using 3D laser scanning in as-built documentation, many more applications exist. For instance, in the future, building officials and other authorities can use the data pulled from the 3D laser scans to clarify misunderstandings. And even facilitate a futuristic type of hybrid building inspection.

Conclusion

In conclusion, when it comes to planning a renovation or addition, accurate site measurement is critical. Using a 3D laser scanner not only ensures precision and efficiency in the design process but also helps obtain building permits and foster clear communication between all parties involved. Don’t let inaccurate as-built drawings cause problems down the line. Work on a reality capture service to obtain your existing site conditions for a smoother project experience. Take advantage of your 3D laser scanning in as-built documentation.

No more delays or costly mistakes due to measurement errors – just accurate and reliable data at your fingertips. Keep your renovation plans on track with the power of 3D laser scanning technology. So, if you’re ready to take the first step toward a successful renovation project, consider scheduling a discovery call.